Office Copy Paper Machine/ Writing Paper Making Machine with Pulp Equipment

Buying Guide

To know well about your requirement and avoid misunderstanding, please check the following information of A4 copy paper machine and feedback us your idea, we can make accurate quotation complete according to your requirement

- What kind of raw material you want to use ?

(1) 100% waste paper;

(2) Waste paper mixed virgin pulp - Production capacity: ___?___ tons/day( 24hours )

- Max width: ___?___mm

- What kind of finished product you want?

(1) Paper jumbo roll;

(2) Paper sheet ( It will be better to supply exact the size);

Machine Models

787mm, 1092mm, 1575mm, 1760mm, 1880mm, 2100mm, 2400mm, 2880mm,3200mm

Brief Introduction

This production line can use waste paper, pure wood pulp, etc as material to make high quality A4 copy paper, printing paper, culture paper,exercise book paper, photocopy paper.Finished products can be paper jumbo roll, paper sheet ( A3, A4, B5 etc which depends on clients requirement ).

This machine include the following section

- Pulp making section

- Press section

- Boiler section

- Hot steam recycling system

- Spare parts

Technical Parameters

Â

| Raw material | waste paper |

| Output paper style | Newsprint paper |

| Paper weight | 40-60g/m2 |

| Paper width | 1700mm |

| Capacity | 10T/D |

| Work speed | 100-120m/min |

| Rail gauge | 2400mm |

| Drive way | AC frequency conversion, section drive. |

Paper Making Process

Raw Materials----Paper Pulp----Jumbo Roll Paper----A4 Paper Sheet / Paper NotebookÂ

Equipment Image

Package & Shipping

- The dryer is packed with wood chips for protecting its surface .

- The large diameter roll is packed with wood chips.

- The steel rolls are packed with plastic film and straw ropes .

- Speed reducer, oil station, and suction box, hydraulic station is packed with wooden box.

- Electric control cabinet is packed with three-ply board box.

- Some parts are nude cargo.

Company Information Â

- Founded in 1988, Qinyang City Shunfu Paper Making Machinery Co., Ltd. is a professional paper machine manufacturer who specialized in manufacturing and exporting paper machine over the past 30 years.Â

- Our products have passed Quality system ISO9001:2000 and exported more than 30 countries, Russia, India, Nigeria, Syria, Pakistan, Egept, Middle East, Africa, and South America etc. Our high quality and perfect service have reserved consumer's praise and more orders.

- Our company view adhering to the "excellent quality, customer satisfaction" service concept, to provide you with excellent products and perfect service.

- Our company keep the contract and reputation. Quality first, products guarantee a year, as it is quality problem, free replacement.

- For every purchase of our company's products, the company can send technicians to guide the installation and debugging, and can undertake the design of process and equipment installation.

- Our company ensure that supply of parts discount all the year round.

If you want to know more information, please contact me!

Office Copy Paper Machine/ Writing Paper Making Machine With Pulp EquipmentÂ

Buying Guide

To know well about your requirement and avoid misunderstanding, please check the following information of A4 copy paper machine and feedback us your idea, we can make accurate quotation complete according to your requirement

- What kind of raw material you want to use ?

(1) 100% waste paper;

(2) Waste paper mixed virgin pulp - Production capacity: ___?___ tons/day( 24hours )

- Max width: ___?___mm

- What kind of finished product you want?

(1) Paper jumbo roll;

(2) Paper sheet ( It will be better to supply exact the size);

Machine Models

787mm, 1092mm, 1575mm, 1760mm, 1880mm, 2100mm, 2400mm, 2880mm,3200mm

Brief Introduction

This production line can use waste paper, pure wood pulp, etc as material to make high quality A4 copy paper, printing paper, culture paper,exercise book paper, photocopy paper.Finished products can be paper jumbo roll, paper sheet ( A3, A4, B5 etc which depends on clients requirement ).

This machine include the following section

- Pulp making section

- Press section

- Boiler section

- Hot steam recycling system

- Spare parts

Technical Parameters

Â

| Raw material | waste paper |

| Output paper style | Newsprint paper |

| Paper weight | 40-60g/m2 |

| Paper width | 1700mm |

| Capacity | 10T/D |

| Work speed | 100-120m/min |

| Rail gauge | 2400mm |

| Drive way | AC frequency conversion, section drive. |

Paper Making Process

Raw Materials----Paper Pulp----Jumbo Roll Paper----A4 Paper Sheet / Paper NotebookÂ

Equipment Image

Package & Shipping

- The dryer is packed with wood chips for protecting its surface .

- The large diameter roll is packed with wood chips.

- The steel rolls are packed with plastic film and straw ropes .

- Speed reducer, oil station, and suction box, hydraulic station is packed with wooden box.

- Electric control cabinet is packed with three-ply board box.

- Some parts are nude cargo.

Company Information Â

- Founded in 1988, Qinyang City Shunfu Paper Making Machinery Co., Ltd. is a professional paper machine manufacturer who specialized in manufacturing and exporting paper machine over the past 30 years.Â

- Our products have passed Quality system ISO9001:2000 and exported more than 30 countries, Russia, India, Nigeria, Syria, Pakistan, Egept, Middle East, Africa, and South America etc. Our high quality and perfect service have reserved consumer's praise and more orders.

- Our company view adhering to the "excellent quality, customer satisfaction" service concept, to provide you with excellent products and perfect service.

- Our company keep the contract and reputation. Quality first, products guarantee a year, as it is quality problem, free replacement.

- For every purchase of our company's products, the company can send technicians to guide the installation and debugging, and can undertake the design of process and equipment installation.

- Our company ensure that supply of parts discount all the year round.

If you want to know more information, please contact me!

Â

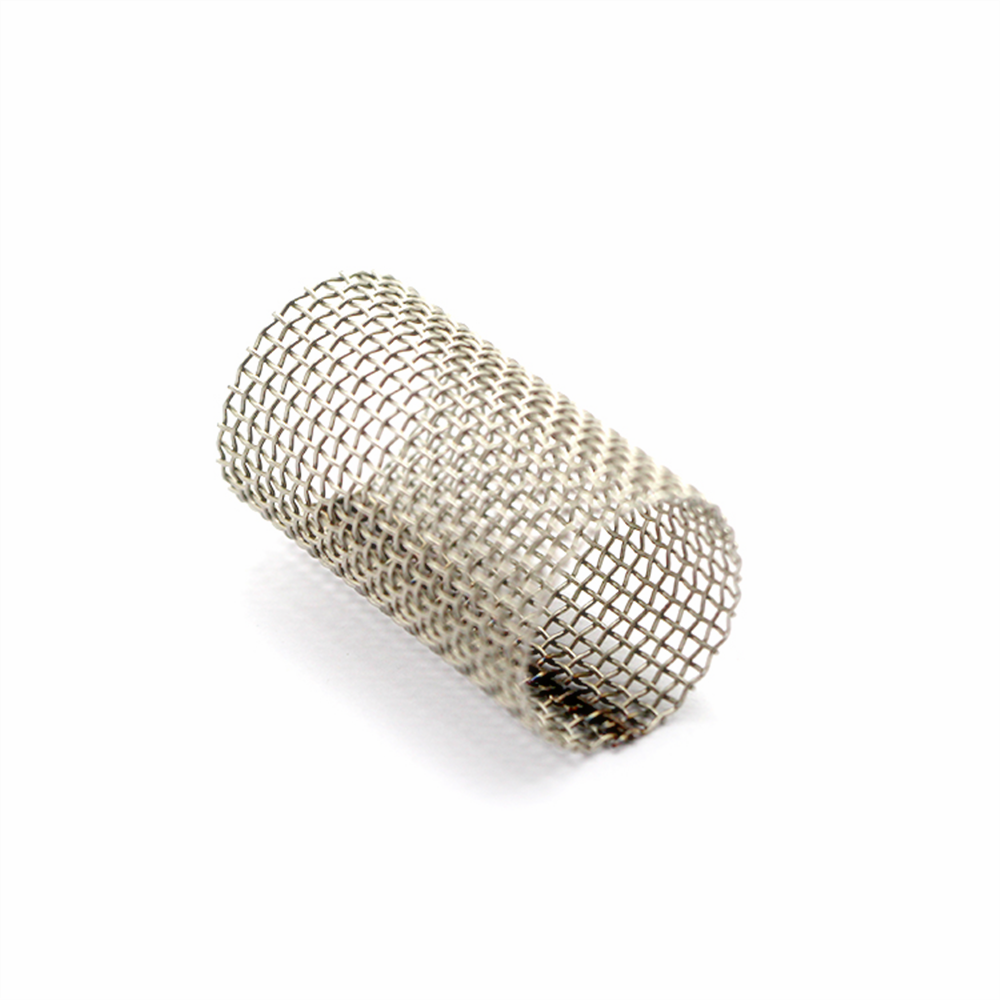

Wire mesh cylinder filter also called wire mesh filter tube ,metal mesh filter tube ,woven wire mesh tube and so on.The wire mesh cylinder filter is made of Stainless Steel Wire Mesh ,galvanized welded wire mesh ,metal perforated sheet, iron wire mesh etc.

Material :SS 201.202.302.304.306.316.316L.Among them,304 316 316L are most commonly used.

Production Process: after cutting, bending, stamping, rolling, welding, polishing and other procedures of production.

Features for wire mesh cylinder filter: good straightness, stainless steel material, heat resistance, corrosion resistance, long service life.

Application :

1) Catalyst filtration and separation;

2) petrochemical high temperature gas filtration, petrochemical plant boiling bed exhaust filtration, catalytic cracking slurry filtration;

3) Purification of high-temperature flue gas in metallurgical industry;

4) Filtration of other high-temperature gases and liquids;

5) Filtration of high temperature, corrosive liquid and catalyst in petrochemical industry;

6) Filtration and purification of various polymer melts in chemical fiber film industry;

7) Filtration and separation of various catalysts in pharmaceutical industry;

8) For gas distribution, liquid bed hole plate material;

9) Used for high pressure backwash oil filter, etc.;

10) Various grout for filtering edible oil, beverage and food;

11) Used to purify and filter production sewage.

SS304 Cylinder Filter Tube,Woven Mesh Screen Tube ,Metal Mesh Cylinder Filter

Suzhou Haoxiang Screen Stencil Products Co.,Ltd , https://www.shaiwanghaoxiang.com