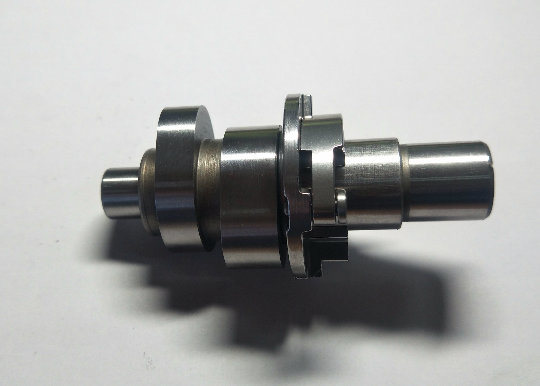

Two Wheeler Engine Parts

Two wheeler engine parts

Production process of powder metallurgy

Powder mixing - Forming - Sintering - Oil impregnation - Sizing -Ultrasonic cleaning - Steam oxidation - Oil impregnation - Final inspection - Packing

A trained, qualified, and dedicated work force

- Engineering is our strength - we will help your designers convert your parts to cost-effective powdered metal parts.

- Every employee is trained to a standard of excellence.

Quality is designed into the process

- Consistent and committed attitude to quality first.

Critical characteristics are measured and controlled using the latest statistical methods

- Quality is always the first priority.

- Our subcontractors are held to the same high standards.

JINGSHI established in 2007 Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â

Manufacturer & Exporter                            Â

Exacting in producing powder metallurgy gears and parts   Â

Passed ISO/TS16949 Quality Certificate                 Â

Advanced Equipment                               Â

Numbers senior R & D engineers and Skilled operators     Â

Precise Examination Instruments.                       Â

Strict Quality Control                                Â

With the "More diversity, More superior, More professional " business purposes, we are committed to establish long-term friendship and win-win relationship with domestic and international customers to create a bright future .

Â

Please Send us your 2D or 3D drawings to start our cooperation!

Â

We are a professional glass cutting machine manufacturer, focusing on the research and development of glass cutting machines for many years

ïµ First Class Parts: All key components are of world class quality, with motors from YASKAWA, racks from Taiwan and so on. All providers are strictly selected to ensure best quality.

ïµ The automatic loading & cutting integrated machine; integrating the function of loading. Linear cutting, irregular shape cutting, air floating, breaking, auto-walking together, it also has remote control function, fully automatically controlling from loading to cutting, which will greatly increase the working efficiency and reduce the cost.

ïµ Highly Automated & Intelligent: using intelligent CNC system to achieve goal of saving humanity and cost down.

ïµ Gas Floatation: improving productivity and in cooperation with take-in and take-out machine, you got a pipe-line machine for cutting, improving productivity maximally.

ïµ Stable and Precise: automatic lubing and pressure adjusting ensures best effects.

ïµ Simple and User-friendly: simple and elegant designing produces simplified operation and management, with the bonus of low maintenance cost.

Glass cutting machine is suitable for curved line cutting of brittle and hard non-metallic materials such as stone, glass, ceramics, etc. It has the characteristics of small cutting arc and easy operation. It is a handy tool for stone, glass parquet industry and home use

Glass Cutting Table Machine, automatic glass cutting line, Glass Cutter, Glass Cutting Machine, auto glass loading machine

Zhengzhou SMART Machinery Manufacture Co.,Ltd , https://www.simamax.com